Preventing Shipping Errors Through Automation and Visibility

Shipping errors continue to be one of the most persistent and costly challenges across industries, particularly for organizations managing high volumes of orders, strict compliance mandates, or multi-site fulfillment operations. Despite the prevalence of enterprise systems, many businesses still rely on manual checks, barcode scanning, or siloed tools to validate outgoing shipments. These outdated methods create opportunities for error and inefficiency, especially when supply chain complexity increases.

Operations, IT, and compliance leaders are recognizing the need for more sophisticated tools that ensure every order is complete, correct, and traceable, without relying on labor-intensive verification processes. Automated order verification has emerged as a proven solution to this growing problem. By implementing RFID-powered order verification software, organizations can significantly reduce the risk of shipping errors, achieve greater operational visibility, and meet compliance requirements with less effort.

The Shifting Landscape of Fulfillment and Compliance

Industries including pharmaceuticals, healthcare, aerospace, and retail are undergoing rapid transformation due to heightened regulatory scrutiny and increasing customer expectations for accuracy and speed. Compliance frameworks such as the Drug Supply Chain Security Act (DSCSA), GS1 Sunrise 2027, HIPAA, and ISO 9001 demand secure, auditable systems for tracking the movement and verification of products at every stage.

Despite these regulatory drivers, many supply chain operations remain reliant on workflows that lack the necessary real-time data and automation. Traditional barcode-based systems often require manual scanning, are prone to missed steps, and do not provide the level of traceability required by modern compliance standards. Furthermore, enterprise resource planning (ERP) and warehouse management systems (WMS) often lack native support for real-time, item-level order verification.

This is where RFID automation delivers a transformative advantage. Automated order verification using RFID technology eliminates these gaps by enabling instant, hands-free validation of every item in an order, without the need for line-of-sight scanning or manual confirmation. When combined with a robust RFID software platform like Avancir, these capabilities become a scalable foundation for error-free fulfillment, compliance readiness, and operational control.

Understanding the Cost and Risk of Manual Verification

Manual verification processes, while often perceived as cost-effective or sufficient at a small scale, become a significant liability as operations grow in complexity. Organizations that rely on human checks and paper-based workflows experience a range of issues that impact performance, customer satisfaction, and regulatory exposure.

Key risks associated with manual verification include:

- Fines, chargebacks, or lost contracts from shipping incorrect items

- Increased likelihood of shipping incorrect or incomplete orders

- Inconsistent verification methods across teams or locations

- Lack of audit trails needed for compliance and inspections

- Delays in catching and correcting order discrepancies

- Higher labor costs from manual checks and rework

In industries where compliance and traceability are critical — such as pharmaceutical distribution, aerospace component manufacturing, and medical device shipping — these risks carry additional consequences. Failed audits, returned shipments, and regulatory penalties can significantly impact both financial outcomes and reputational trust.

The Role of RFID Automation in Order Verification

Automated order verification powered by RFID technology allows organizations to replace subjective, inconsistent manual checks with a scalable system of real-time, data-driven validation. Each item tagged with an RFID label can be identified and confirmed automatically as it moves through picking, packing, and shipping workflows. This hands-free, high-speed data capture ensures that order contents match what was promised, before the shipment leaves the facility.

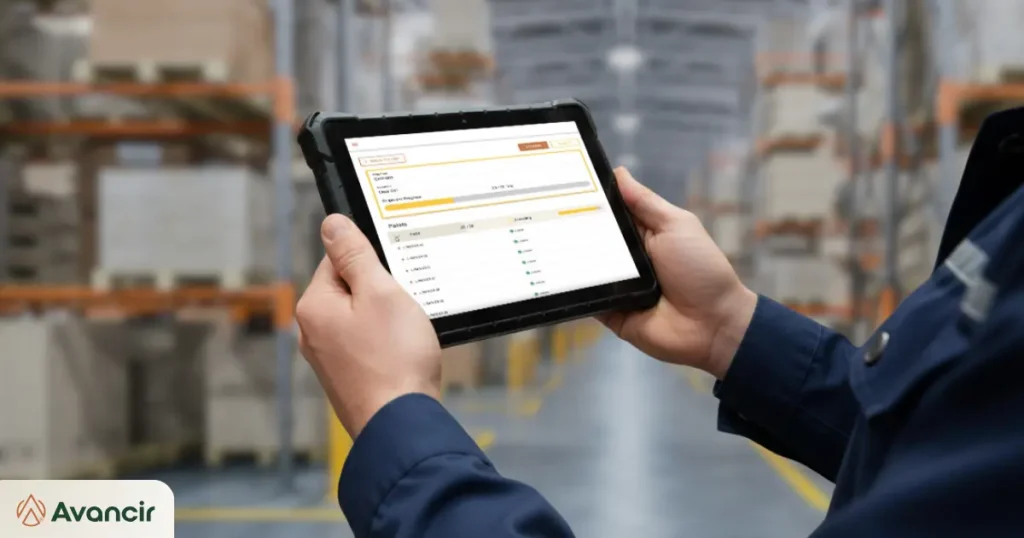

Avancir’s RFID platform enables teams to build verification checkpoints directly into their existing processes. Whether using fixed readers at dock doors, handheld scanners at pack stations, or portals in high-throughput zones, organizations can configure rules to ensure every outbound order is complete, compliant, and documented.

Key advantages of RFID-based order verification include:

- Simultaneous scanning of multiple items without line-of-sight requirements

- Automated detection of order mismatches or missing items

- Timestamped, searchable audit logs for compliance traceability

- Configurable workflows to support varied product categories and regulatory needs

- Seamless integration with ERP, WMS, and MES platforms for synchronized data

By eliminating the need for manual intervention, RFID-powered order verification allows supply chain teams to reduce error rates, accelerate order processing, and maintain high standards for both operational performance and regulatory compliance.

How RFID Can Help Eliminate Shipping Errors Across Industries

When accuracy and compliance matter, manual verification simply can’t keep up. RFID automation offers a smarter, more reliable way to verify outbound orders and reduce costly mistakes. Here’s how organizations in key industries could use Avancir to improve fulfillment and reduce risk:

Pharmaceutical Distribution

Distributors preparing for DSCSA compliance can use Avancir to automate the verification of serialized medicines during packing. By integrating fixed RFID readers and rule-based validation, teams can reduce packing errors, ensure the right products are shipped, and generate audit-ready records for FDA inspections without slowing down throughput.

Aerospace Manufacturing

In environments where every part matters, aerospace manufacturers can replace manual kit verification with real-time RFID tracking at the point of assembly. Avancir enables automatic checks to confirm every item is in place, improving inventory accuracy, reducing inspection time, and creating full visibility across production workflows.

Retail and Consumer Goods

As GS1 Sunrise 2027 approaches, retailers can use Avancir to validate serialized product data at scale. RFID automation helps confirm outbound shipments are accurate before they leave the dock, reducing returns, improving customer satisfaction, and simplifying compliance with item-level traceability standards.

Building a Scalable RFID Verification Strategy

Successful implementation of RFID order verification starts with a strategic approach that aligns technology with business goals and compliance requirements. Organizations do not need to replace their existing systems to achieve results; instead, they can layer RFID automation into existing workflows to quickly improve accuracy and efficiency.

Recommended steps for implementation:

- Map Your Current Fulfillment Workflows: Identify where order verification currently occurs, where errors are most common, and which products carry the highest compliance risk.

- Select High-Impact Use Cases: Begin with outbound order verification for high-value or regulated products, where visibility gaps are most costly.

- Choose an RFID Platform That Supports Integration: Avancir offers integrations with leading ERP, WMS, and MES systems, allowing seamless synchronization of verification events and item metadata.

- Configure Rules for Automated Validation: Define acceptable item types, quantities, and packaging requirements for each order type. Avancir’s software enables teams to build custom workflows.

- Deploy and Monitor: Use fixed and/or handheld readers to begin capturing RFID data at key verification points. Monitor performance, analyze error trends, and scale the solution to additional workflows or sites as needed.

By following this approach, teams can implement RFID order verification quickly and iteratively, proving value within a matter of weeks and expanding the system as operational needs evolve.

Click here to download our free guide on how to choose and deploy the right RFID solution for your business operations.

From Error-Prone to Audit-Ready Fulfillment

Shipping errors, compliance gaps, and manual verification processes no longer need to be accepted as the cost of doing business. RFID automated order verification offers a proven, scalable method for improving fulfillment accuracy, maintaining regulatory compliance, and supporting operational growth.

Avancir’s order verification software provides a comprehensive platform that combines real-time RFID automation with the flexibility and integration support modern supply chains require. Whether your organization is preparing for DSCSA, GS1 Sunrise 2027, or internal quality audits, Avancir makes it possible to eliminate shipping errors with RFID, automate your order checks, and operate with confidence.

Start your RFID journey today and request a free demo of Avancir to create an RFID solution that fits your unique order verification process.